Specializing in make-to-order cutting tool manufacturing for over 80 years and three generations.

80+

Years in Business

20k

Sq Ft Facility

300+

Customers Served

8

Automation Units

OUR CAPABILITIES

-

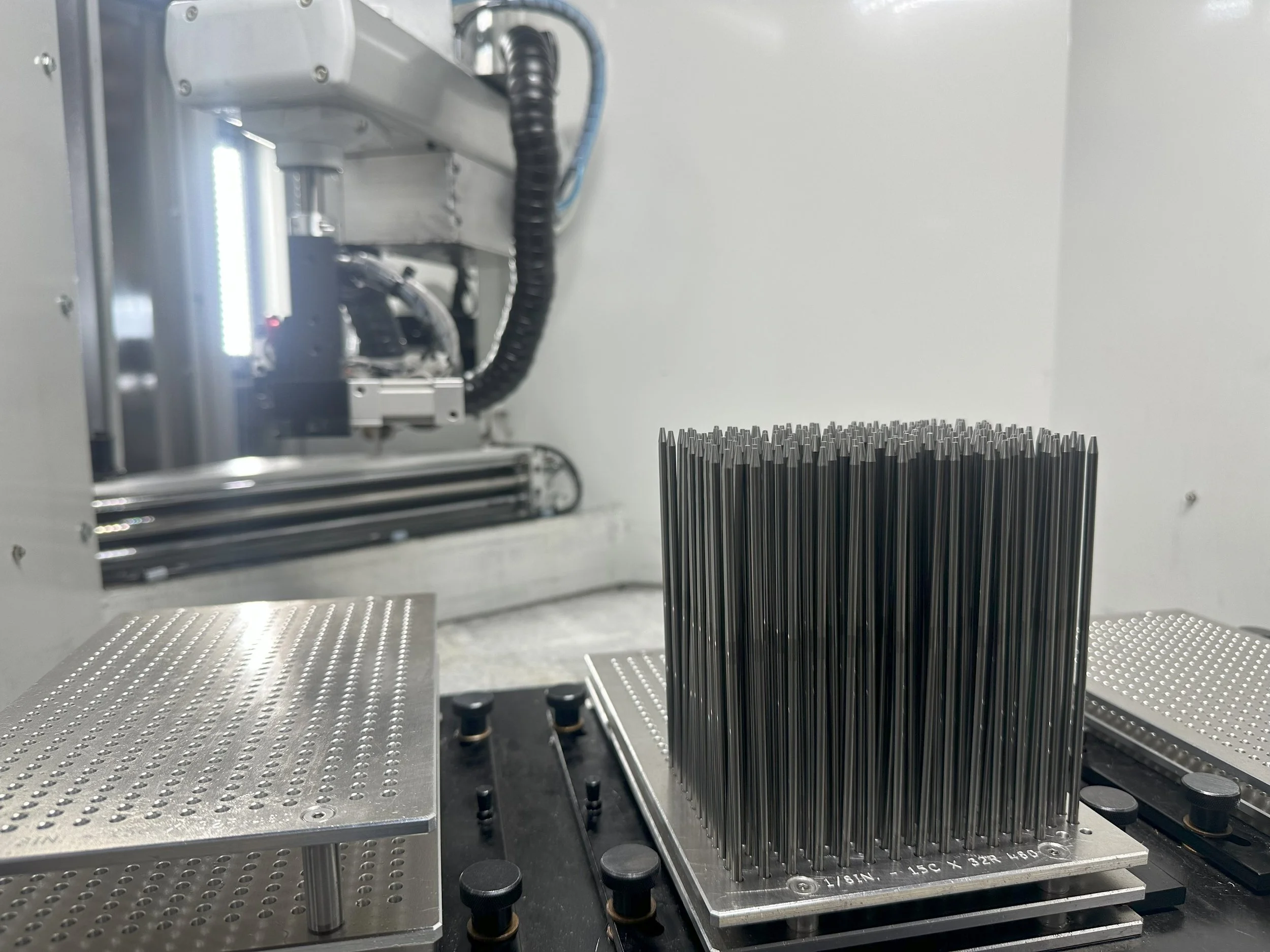

Series of Walter Helitronic and Anca FX Series Cutter Grinders (with Automation) for premium accuracy and enhanced productivity

-

Series of TruTech Systems Taper/Plunge/Form grinders (with Automation) for intricate profiles

-

TruTech Systems CNC OD Grinder and conventional OD grinders on site for extreme straightess and concentricity

-

HAAS VF4 CNC Mill with 5 Axis Rotary for enhanced capability and heightened productivity- series of conventional 3-axis Milling machines on site as well

-

HAAS ST20y CNC Lathe with integrated live tooling (with Automation) for turning complex tool bodies and precision round parts with intricate features

-

NC controlled automatic surface grinder for precision flatness of carbide / steel tools, multiple well-maintained manual surface grinders for intricate finish grinding

-

Conventional Winslow Drill Point Grinder on site for enhanced capability / support

-

Highly skilled personnel utilizing torch brazing and multiple induction units for brazed-tip constructions, conventional furnace for heat treating steels for increased hardness

-

Both AutoCAD (in DXF formats) and Fusion 360 utilized for tool drawings and programming

Up-to-date software on all production CNC machines

OUR DIFFERENCE

Highly skilled employees with over 400 years of cumulative toolmaking experience

Numerous awards and recognition for quality, delivery, and service from our customers, including a Diamond rating from Boeing Corp.

Quality Control and Employee Training 100% compliant with NAS Standards for aerospace and ISO 9000 for automotive

Statistical Process Control and in-process inspection used for consistent, dependable quality

INDUSTRIES SERVED

-

Aerospace

As a supplier for many commercial aircraft, rocket, and defense end-users, we manufacture a wide variety of special aerospace tooling (both carbide and high-speed steel) that meets the high precision and quality standards demanded in this ever-expanding industry.

-

Automotive

With our cumulative years of experience producing specialty step drills/reamers/end mills for the automotive industry, whether it’s for engine components, fuel systems, shifters, or anything else, our team is sure to meet your specifications.

-

Woodworking

Here at PTC, we’ve made custom carbide-tipped router bits for our customers since the 1950s. With our enhanced capabilities over the years, our capacity for specialty woodworking tools is near limitless. Dovetail cutters for cabinetmaking, solid carbide compression router bits for CNC, squaring/tenoning bits, specialty saws, you name it.

-

...And Many More!

We continue to serve a diverse set of customers within a wide range of industries, including medical, waterworks, construction, mining, spring forming, die-cast, trucking, firearms, and even the beverage industry. Our highly skilled team delivers on the promise: if you need it, we will make it!

Work with us today!

We’ll get you what you need